As mentioned in an earlier post, I decided to do a post and beam foundation with several of the posts going through the floor into the wall. Kind of a pole barn/platform framing combination.

Reason? I thought it would be cheaper than paying for all that concrete, a notion that will probably be proven false with the cost of rental equipment thrown in along with materials. Another reason is oddly enough, earthquake resistance. I know we’re not exactly known as the earthquake center of the country here in southwestern Missouri, but we do have the New Madrid fault that when it last cut loose, turned the Mississippi river up stream. So, as long as I have a chance to be prepared, why not?

It’s been hot: 95 degrees with a heat index of over 100. So, it doesn’t take long to get soaking wet, top to bottom. I take lots of breaks—no hero here—and find some shade. So, that might explain the apparent slow pace of this project. But our impending deadline keeps me going. We need to be out of our current house by Sept 4, 2010. Since the cottage will not be done, we’ll live in a travel trailer on the property until it is.

John, my carpentry friend from church formed up a couple of things for me. This is a footing for a future masonry furnace. It will bear over 30 tons of rock when the beast is done, so I’m pouring an 8” thick footing.

And here’s a recognizable feature: The front walk and pad for the stairs off the porch. I thought about mixing bags of concrete for the posts, but after calculating that I’ll need over 60 bags, I decided to pay a little extra and have a truck come out. And, as long as I was bringing out a truck, might as well pour whatever I can. Hence, the footing and walk.

First step was digging 28 holes. Most were 18” in diameter and a couple were 30”. The reason for such large holes is the limited carrying capacity of the soil: Clay. At 1,000 or 1,500 psi, you need a larger foot print at the bottom of the hole to carry 2,000 – 4,000 pounds per post. So, with the larger hole, I can pour a collar around the base of the post, which provides a larger surface area for the soil to carry the weight.

Also, at the bottom of each post, I drilled 1/2” holes at 90 degree angles from each other and drove one foot long pieces of rebar, forming a cross. This will provide a positive connection between the concrete collar and the post.

In this area of the county, digging by hand is nigh impossible, especially for an old out of shape man like me. Answer, skid steer with auger attachment. Very efficient at digging holes, but at $400 a day, not the cheapest solution. Here’s a short look at the 30” bit in action. (Note that during the video you’ll hear the bit hitting rock (surprise!). To get the center post deeper than what the 30” auger would go, I drilled further with the 9” bit.

After digging the holes, we set the posts into the holes. Here’s where my good friends saved Connie and me a ton of work (actually, we wouldn’t have been able to do this alone). Matt and I were lifting a 16 foot 5x5 treated post into one of the holes. He let go to come around the front, and the post just kept getting heavier and heavier until I was on the ground feeling very weak and un-manly. So, the help was wonderful.

Here’s a shot of all of the holes dug, all of the posts in the holes, and some of the posts set and braced. Now I’m just praying for dry weather until I can finish setting the posts and getting the concrete truck out here. Hopefully, by Tuesday or Wednesday. Once the concrete is poured and the holes are backfilled with dirt, I’ll breath easier.

I’ve been helped a lot this week by some very dear friends from the branch who showed up and volunteered to help: John, Cameron, Matt, Tommy, Ben, and Mike. Great help and just when I needed it. I’m sure Connie appreciated it because she would have been on the other end of those posts—and they’re heavy.

Here’s John, Cameron, and me showing what manly men look like at rest (notice the large lumber pile holding up our back sides). Just to be clear, they ate watermelon too. I didn’t hog it all for myself.

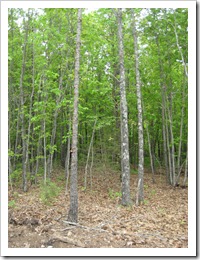

It took longer than expected, but we now have about a 300 x 200’ clearing in the middle of the woods along with the power easement cleared from the nearest pole on the property.

It took longer than expected, but we now have about a 300 x 200’ clearing in the middle of the woods along with the power easement cleared from the nearest pole on the property.  The easement required a 30 foot wide cut for about 800 feet in preparation for bringing power to the building site. The power company engineer will be out on Tuesday to take final measurements and place stakes where the poles will go. If they have to place more than two poles to get to the building site, it costs $100 per pole and $75 for each guy wire. So, the straighter the shot the better so as to avoid extra guys. Still, I hated to clear that

The easement required a 30 foot wide cut for about 800 feet in preparation for bringing power to the building site. The power company engineer will be out on Tuesday to take final measurements and place stakes where the poles will go. If they have to place more than two poles to get to the building site, it costs $100 per pole and $75 for each guy wire. So, the straighter the shot the better so as to avoid extra guys. Still, I hated to clear that  We drove around today to get another look at the fire damage and was surprised at how quickly the grass has grown. In fact, in open areas, you can hardly tell there was a fire. Many of the old dozer piles were consumed by the blaze, which is a good thing.

We drove around today to get another look at the fire damage and was surprised at how quickly the grass has grown. In fact, in open areas, you can hardly tell there was a fire. Many of the old dozer piles were consumed by the blaze, which is a good thing.

The oaks are just beginning to leaf out. Please indulge me for a one more picture. This is looking northeast from the west end of the property.

The oaks are just beginning to leaf out. Please indulge me for a one more picture. This is looking northeast from the west end of the property.  The little hill you see is known locally as Dove Mountain. The use of the word mountain is strictly an Ozarkian term that means little hill slightly higher than the other little hills. Hey, it’s all we have out here. Anyway, it’s reported to be the second highest point in Missouri and is the vestige of an old volcano. You can still find plenty of volcanic rock in the west end of my property.

The little hill you see is known locally as Dove Mountain. The use of the word mountain is strictly an Ozarkian term that means little hill slightly higher than the other little hills. Hey, it’s all we have out here. Anyway, it’s reported to be the second highest point in Missouri and is the vestige of an old volcano. You can still find plenty of volcanic rock in the west end of my property.