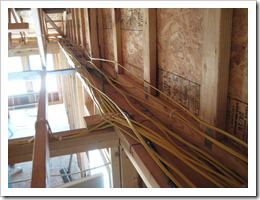

(7/9/2011): Been working on running electrical in the house for a couple weeks now. As usual, this has taken longer and cost more than expected (big surprise). But yesterday, I ran the last lighting circuit and this morning I’ll run the circuit for the two smoke detectors. I’ve tried to follow the NEC (electrical code), even though there’s no building permits and inspections in this county (thankfully, which is one reason I’m here). I ran the cables around the perimeter of the building in the attic, rather than across the attic:

When I started the electrical work, I used a 1/2” auger bit to drill through studs when needed. However, I found that this was too small and was causing difficulties when trying to turn a corner (the cable was getting bunched up). Also, I often needed to run more than one cable through the top plate and ended up having to drill multiple holes in the same stud bay. So, I switched to a 1” spade bit and that worked better.

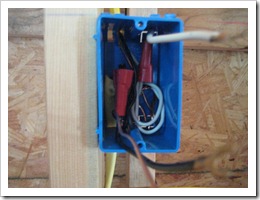

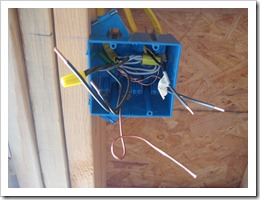

Some shots of the wiring:

I ran dedicated circuits for all 220 devices:

- Range, 50A (6-3 cable—this stuff was very expensive: 125’ roll for $256. Ouch!)

- Dryer, 30A (used left over 6-3, which is overkill, this stuff is gold)

- Water heater, 30A (used 10-2 direct bury cable I had on hand)

- Two PTAC units, 20A (combined heat pump heaters and air conditioners—this is my primary heat/cooling now and will become secondary after I build the masonry furnace). I ran standard 12-2 NM cable.

- Base board heater in bathroom, 20A (again, used 12-2 NM)

As you can see, I decided to wire everything electric rather than rely on propane for the key energy hogs (range, dryer, water heater). There’s a reason for this. I aim to become totally energy independent and long term reliance on the propane truck is not desirable. However, permanent dependence on the grid is equally undesirable. In the future, I will be building a solar water heater and use the electric water heater has backup. I’ll probably build a solar PV system for some electric use, but have my eyes on an emerging technology that I think will allow me to burn trash and biomass to generate electricity (see Abundant Energy Works).

Although PV (solar) is a good way to power some of a home’s electrical needs, it is not a total energy independence strategy if you have to switch dependence to propane for major appliances. It seems to me that to be totally energy independent, one must either dramatically change one’s life patterns or spin a generator. At this point, I’m planning on eventually spinning a generator, but we’ll have to see how things go.

The other reason I’m building a 100% electric house is that it’s quicker and easier to move into. We need to get out of this trailer! If later, we decide we need to run propane, we will. For now, I’ll use the propane tank to eventually run an emergency generator. Propane is a great solution for an emergency standby generator fuel, since it will last forever in the tank. So, I may not have the total energy independence strategy worked out, but I know the first couple of steps: Get into the house and buy/build an emergency generator that runs on an internal combustion engine fueled by propane.

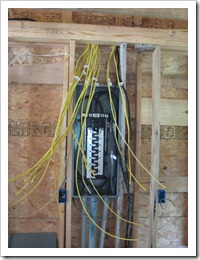

I am using a Square D Homeline main box. I don’t think I’ll use the Homeline box again in the future. The busses are aluminum and not copper; the plastic in the box seems to be on the cheap side; there is space for only 30 single-space breakers instead of the expected 40; and the breakers are hard to put on and take off. Also, I just learned that the breakers for the Homeline brand are more expensive than other brands. I think I’ll stick with commercial quality in the future.

With the installation of the smoke detector circuit today, I’ll fill up the box except for one space for a future breaker, which is not what I wanted. It was a surprise and a disappointment to find the box only had space for 30 circuits. I hate filling the box on day one, but I have no choice.

I wired all 110v circuits using 12-2, except for the dedicated freezer circuit, where I used 14-2 cable (this is ok according to code). Used a total of almost 1500 feet of 12-2 cable. I have two GFI circuits for the kitchen receptacles above the counter and a separate GFI circuit for the bathroom receptacles. The bedroom receptacle circuit will use an arc fault circuit breaker. I ended up with two 3-way switched lights, for which I used 14-3 cable. The lighting was divided up on four lighting circuits.

Seems like a lot for a 1000 square foot, one bedroom cottage. It does add up. Connie thought I went overboard on lighting, which, knowing me, I probably did. But, I don’t think my eyesight will get any better and I want to make sure I’ve got enough light.

Now, to finish the rough electrical, I need to populate the main box and install pigtails in all the boxes. By that I mean that if a receptacle has power coming in and power going out I connect the grounds, neutral, and hot wires with pigtails so that when I later install the receptacle, there are only one set of hot, neutral and ground wires. Once these two tasks are done, I’ll move on to rough plumbing.

Above is an example of wiring a receptacle box using pigtails so that there is only one white, one black, and one ground wire to connect to the receptacle.

For a double switch box, I also used pigtails so that I ended up with two incoming power lines (one for each switch), a black for each of the light switches, and one ground that will be connected to both switches in series. Note that I’ve pushed back the ground wires first, followed by the white and finally the black wires.

Here’s a shot of the box before populating it:

Here’s what it looked like after pulling all the wires into the box.

(7/14/11): And here’s the finished box. I loaded all the 220v breakers on the right and all the 110v breakers on the left. On the 110v (left) side, I loaded up the receptacles first at the bottom, then the bath receptacles, the kitchen receptacles, followed by the light circuits on the top, with the exception of putting the smoke detector circuit (15A) on the top right breaker.

I’m definitely not a licensed electrician, but some things I always keep in mind when I’m wiring:

- Get a good book on wiring a house. I use “Wiring a House” by Rex Cauldwell, published by Taunton Press (this is the “For Pros By Pros” series and is very good. I have several of their other books in the series and find them excellent. I refer to them often.

- Use 20A (12-2) wire for all circuits except dedicated fridge and freezer, and smoke detectors, in which case I use 14-2. Use 14-3 cable for 3-way switches or between smoke detectors (to make them all go off if any one is activated—this is code for new construction). Just make sure that you use a 15 amp breaker in any circuit where you use 14 gauge wire that can carry the entire load of the circuit.

- Bring power into the top left opening of all boxes. I usually take the power out cable in the bottom left and then any runs to lights, to the top right knockouts.

- Where possible, I try never to run wire through the center of the attic where it would be easy to step on or trip over. I usually run cable around the outside of the structure in the attic and then if I need to come into the middle, staple the wire to the side of a truss/joist member.

- I run the large cables first (range, dryer, water heater), then do the 220v and 110v dedicated lines (air conditioners, fridge, freezer, washer, base board heaters, etc., followed by the receptacle circuits, and finally the lighting circuits.

- Split the receptacles above the kitchen counter top between two dedicated circuits. Use at last one dedicated receptacle circuit for each bathroom and one for the Laundry room.

- You can’t have too many receptacles. Code specifies at least one within six feet of a doorway and then at least one every 12 feet along walls. I usually do almost twice that many.

- Use a 1” spade bit or equivalent to drill holes in top plates and through studs. In most cases, more than one cable needs to be pushed through the hole anyway. Probably not a good idea to bring more than four 12-2 cables through one hole.

- For lights, I always run the power into the switch box (instead of the ceiling box) and then just run one cable from the switch to the light box. This makes it easier to troubleshoot because all the wires are in easy reach.

- If I ever need to splice a wire (I try and avoid this, but in some cases, I make a mistake and need to lengthen a cable), nail on a box, in the attic, out of the way, connect the wires, and install a closed cover plate. (Never hide a junction box within a wall and then cover it with sheet rock.)

- Cut two large, elongated holes in the top plate above the main box. I usually drill two 2” holes about six inches apart on each side and then cut out between them using my reciprocating saw. Through the hole on the left, I bring in all the 110v home run cables. Through the one on the right, I bring in all 220v runs.

- Label all cables coming into the main box. When first running cable, just bring the wire to the main box (through one of two large holes in the top plate above the box), and just let it hang in front. Be sure and cut the cable so that it hangs to the bottom of the main box. I place a label, using masking or freezer tape and a permanent marker, around the cable just above the top of the box.

- Pigtail each box, as appropriate. For example, for a double switch box with power going in and out, connect all four ground wires along with an extra piece of longish ground wire using a red wire nut; connect all four neutrals (white) using a red wire nut; then, connect the two black wires from the power in and power out, along with two additional black wire pigtails. When finished, you’ll have two blacks for one side of each switch along with two black wires going to their respective lights on the other side of the two switches (and a ground wire, of course).

- In double and triple boxes, the one longish ground wire is hooked to each switch’s ground lug in series by looping the wire and tightening the loop around the ground lug.

- Within a box, to ensure you have enough room for the switches/receptacles, push back the connected ground wires first, followed by the white (neutral) wires, with the black (hot) wires remaining towards the front. I use the handle of a hammer to push each set of wires to the back of the box.

I connected the main service cable at the pole to the lugs on the main switch box, turned everything on, and amazingly, nothing blew up. Currently, I have lights, the switch, and a receptacle all completely wired with face plates in the attic. Last night, we turned on the appropriate breaker (after ensuring that the wires in all of the switch boxes, receptacles, and ceiling boxes on that circuit were not touching) and turned on the switch to the attic lights, and WOW, it worked. So, we now have our first lights working in our little house.